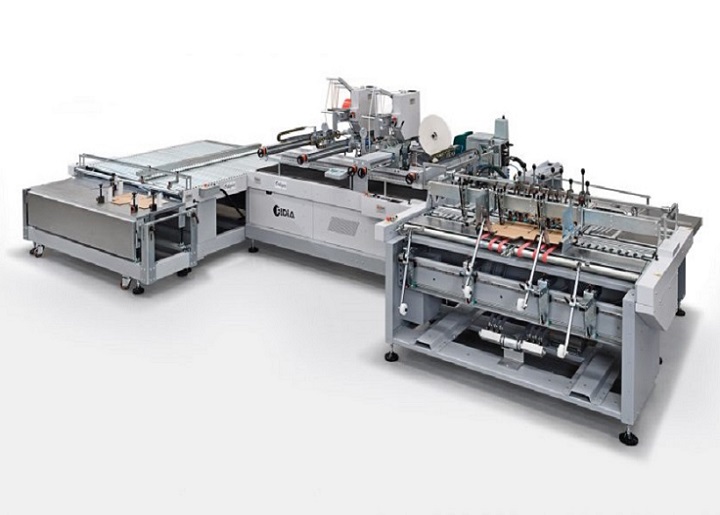

Tape Application Machine

In the world of e-commerce, efficiency and innovation are key to success. The Ortigia tape application machine from Fidia Macchine Grafiche represents an advanced solution for large format packaging, offering high-quality functionality to meet the demands of the modern market.

E-commerce Packaging

As we grow and evolve with the e-commerce packaging market, Fidia introduces new machines and innovations to its product line. The Ortigia tape application machine is specifically designed to apply tear tape and double-sided tape on large format corrugated boxes, also known as e-commerce packaging.

Features and Benefits

We use double-sided and tear tape strips for resealable boxes. The external double-sided tape is used for closing the box and sending it out. The central tear tape is used for opening the box, and the internal double-sided tape is for closing the box again for returns.

The machine includes our Speedy double-sided tape applicator, the Altor tear tape unwinding system, and a customized large format feeder. Notably, we can install our applicators on almost all Fidia machines, as well as on other folding and gluing machines from different manufacturers.

High-Tech Solution for High-Quality Packaging

The Ortigia automatic packaging machine was developed through extensive design and experimentation. The goal was to create a machine capable of performing multiple operations on a single production line, delivering high-quality packaging as the finished product.

Designed for Efficiency and Versatility

The Ortigia tape application machine is tailored to meet the needs of any company looking to produce functional, original, efficient, and durable packaging. It operates at high speed to optimize production costs, making it an ideal choice for businesses aiming to enhance their packaging processes.

Fidia’s Expertise in Automatic Packaging Machines

Fidia has been producing automatic packaging machines for e-commerce, shopping, and boutique packaging for over 30 years. Our extensive experience in the graphic world allows us to design perfect packaging machines that meet the highest standards of quality and efficiency.

Specifications

Continuous Feeder:

- Independent continuous top-loading friction feeder

- Maximum format: 200 x 120 cm

- Minimum format: 50 x 40 cm

- Mechanical double sheet detector

- Loading capacity: 200 mm (depending on weight and format)

- Vacuum system on belts

- Maximum carton thickness: 3.7 mm

- Production speed: from 1,500 up to 4,000 copies per hour, according to the format

General Characteristics:

- Roller side lay alignment

- Three working positions after the side lay register table